Warehouse Safety Audits - Consultancy

Independent Warehouse Safety Audit and Consultancy Solutions

IFC (World Bank Group) Approved Independent Consultant

2K+ safety assignments

in last two years

India, SAARC Countries & Middle East

Ready to serve anywhere you are

14+ years

at the forefront of Safety Advisory Space

20+ types of Industry Sectors

covering Manufacturing, Mining, Power & Utility, Construction, Services, High Rise Buildings, Warehouses, Hospitals, Logistics and many more.

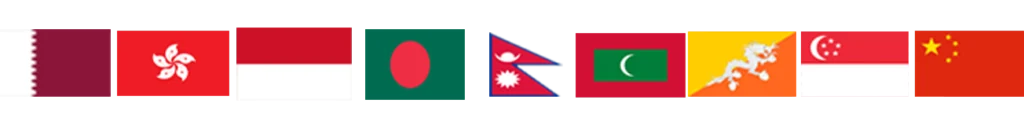

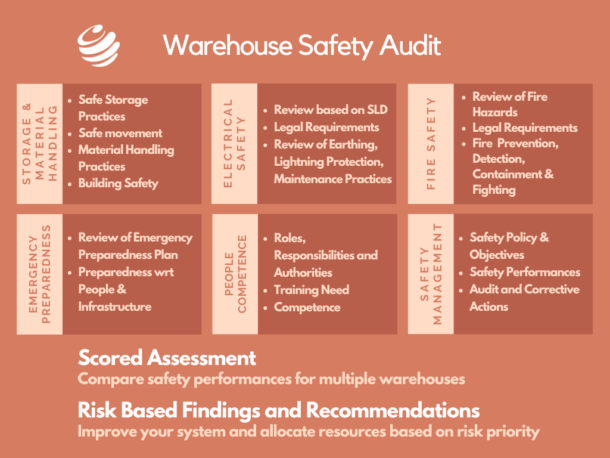

Warehouse Safety Audit and Consultancy Solutions

Consultivo ensures safe warehousing practices through our Warehouse Safety Audit and Consulting Solutions covering Statutory Rules, Standards, Company Requirements, and Good Industry Practices.

Warehouse Safety Audits bring insights on the current hazards, level of risks and effectiveness of the existing control measures.

Warehouse Safety Consulting Solutions help organisations to bridge the gaps against requirements, thus implementing a robust Safety Management Systems.

It's a Scored Assessment

You get a quantitative outcome of your safety performance and can compare multiple warehouses with this scored diagnosis tool. Warehouse safety audits identify gaps in current control measures with respect to national/international standards and legal requirements.

You'll get Risk Based Findings & Recommendations

Improve your system & allocate resources based on risk priority. Our audits provide recommendations suggesting suitable risk control and mitigation measures for improvement.

Warehouse Hazards and Safety Tips

Consultivo ensures safe warehousing practices through our Warehouse Safety Audit covering Statutory Rules, Checklist, and Good Industry Practices.

Warehouse safety audits bring insights on the current hazards, level of risks and effectiveness of the existing control measures.

Forklifts

Forklifts are very frequently used in warehousing and storage facilities across the globe irrespective of the type of storage. However, when operated incorrectly can cause serious damage to operators, nearby workers, and property. Unsafe use of forklifts is the most often cited hazard in the domain of warehouse safety. Tips: Ensure proper equipment health along with all safety controls, pre-start inspection and competent (trained and retrained operator, medically fit with safe behaviour)

Manual Lifting and Handling

This is one of the most common causes of physical injuries in warehouse and storage facilities. Manual lifting or handling can cause physical injuries and musculoskeletal disorders in case of awkward postures, repetitive motions. Tips: Ensure proper equipment or engineering controls to eliminate or reduce manual handling. An ergonomic study can help to reduce warehouse safety hazards related to awkward postures and repetitive motions.

Storage of dangerous goods/hazardous chemicals

A number of hazards may be created when storing packaged dangerous substances. These warehouse safety hazards may affect people working within the storage site, the emergency services in the event of an incident, the general public off-site, and the environment. Fire is generally considered to be the greatest hazard, associated with toxic fumes, explosions. Tips: Identify Chemical Safety Hazards through HIRA. Different types of dangerous substances are to be assessed based on hazard classification systems to formulate a risk control strategy. It will ensure controls including sufficient segregation, storage conditions, handling precautions, etc. Interaction between different dangerous substances may create additional hazards.

Electrical and Fire Hazards

One of the most common hazards in warehouse and storage facilities. Tips: Ensure proper equipment or engineering controls to eliminate or reduce electrical & fire hazards. A detailed electrical & fire risk study can help to reduce such risks. Fire drills are very important to keep the fire fighting system in place. Download our Free Handbook for Electrical Safety Precautions and Electrical Safety Checklist

- Safe storage practices including building safety

- Material handling, forklift movement & fleet movement

- Manual handling, loading & unloading

- Legal compliance and warehouse safety rules

- Fire management prevention, detection, containment & fighting

- Emergency preparedness

- Electrical safety

- People competence related to warehouse and safety

- Safety management system & safety performance

- A unique risk-based report with scored assessment

- A management dashboard with scientific data visualization through graphs, charts, heat maps

- Identified gaps against statutory requirements, national and international standards with a risk rating

- Recommendations for closing the gaps

- Industry experienced competent auditors

Find more: Combined Audits on Fire and Electrical Safety

Let's discuss

Impact Stories

The impact we create. The excellence we inspire.

Read a few of our stories as we partner organisations as an ESG and Sustainability Consultant Company and an Advisory Firm.

The internationally reputed company is a major construction, mining and power solutions provider with more than 25 locations in India. Their major challenge was working with multiple standards and legal requirements of different stakeholders.

We started with the development of an inhouse standard and guideline which was implemented across the locations.

We customized our scored assessment protocol ‘Protosafe’ as per their requirements and developed a three year plan. The safety performance scorecard provided the required guidelines to the management for improvement. Our recommendations facilitated the actions.

A definite positive trend of improvements observed in the subsequent years.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

25 Locations across India

4000+ workpersons

Since 2018

Project ongoing till April 2023.

An international automotive manufacturer intended to reduce the OHS risks across the value chain – dealers/workshops. We created a customized OHS audit protocol keeping the focus on the relevant potential hazards and risks. The outcome includes analytics, scoring, benchmarking among the entities.

The project is ongoing for 1200+ units across India.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

1200+ units

A large Naphtha Based Petrochemical Complex needed statutory safety audit as per IS 14489 standard. This audit was intended for meeting compliance and finding out potential risks from an independent expert perspective.

Consultivo was selected after a rigorous technical evaluation process which was focused on the quality of experience and expertise of both the organization as well as the auditors. The team was carefully chosen with diversified expertise in General Safety, Fire Safety, Process Safety and Electrical Safety with adequate Oil & Gas (Refinery & Petrochemical) experience.

The audit was conducted as per IS 14489:2018 standard and a detailed report was submitted with specific gaps, risks and recommendations.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

One Location with Naptha Cracker Unit and 12 Associated Plants

Captive Power Plant

Pipeline to Jetty

Featured Insights

Knowledge Bank

Impact Stories

Impact Stories

Impact Stories

Impact Stories

Impact Stories

View more in Impact Stories | Blogs | Knowledge Bank | News and Events

Curiosity Zone

Some more answers to your questions – FAQ

Warehouse Safety Audit

Safety Audits for Warehouses help an organisation or a supply chain to identify

- Safety hazards related to the entire warehousing operations

- Building Fire and Life Safety risks and

- Risks associated with the key operations, safe working of employees and their level of controls

These insights and practical recommendations that are provided along with the audit, help the supply chain to mitigate occupational health & safety risks.

As a leading Safety Consultancy Company in India and it’s neighboring countries, Consultivo provides independent and unbiased industry specific solutions in the areas of Hazardous Area Classification HAC, Fire Safety Audit, Electrical Safety Audit, Electrical and Fire Safety Audit, Thermographic Study, Safety Legal Compliance and many more.

View our complete range of Safety Consultancy

Warehouse Safety Audit Checklist

Warehouse safe practice checklist or warehouse safety audit checklist is a comprehensive tool which helps the operating staff to manage and maintain the overall aspects of safety requirements.

Generally, there can be two types of Checklists – Generic and Site Specific. It is always advisable to develop industry sector and site specific checklists for the warehouses.

A good Warehouse Safety Checklist generally includes company requirements, relevant warehouse safety rules and industry good/best practices.

GLOBAL Experience