Hazardous Area Classification – HAC

Independent Risk Management & Consulting Solutions

IFC (World Bank Group) Approved Independent Consultant

2K+ safety assignments

in last two years

India, SAARC Countries & Middle East

Ready to serve anywhere you are

14+ years

at the forefront of Safety Advisory Space

20+ types of Industry Sectors

Covering Manufacturing, Mining, Agri-Business, Power & Utility, Warehouse, Construction, Services, FMCG, Logistics and Many More.

Consultivo conducts Hazardous Area Classification services.

As one of the practicing Hazardous Area Classification Consultants in India we facilitate proper selection and installation of electrical equipment to be used safely in that environment without any commercial bias.

Hazardous Area Classification is the process of identifying and categorising zones where flammable gases, vapours, liquids, or combustible dusts are present. The purpose is to determine appropriate safety measures for each area and equipment needed to prevent potential fire or explosions to ensure safe operations.

Classification of Hazardous Zones are done based on the applicable guides and standards and properties of the flammable materials that may be present.

Hazardous Areas Classification or HAC was primarily used for choosing electrical equipment to prevent ignition in hazardous atmospheres. Now HAC is being applied in risk assessments to areas that can contain flammable vapours, gases, combustible dust, or fibres.

The classification includes the zoning of the areas handling –

- Flammable chemicals according to IS 5572 and IEC 60079-10-1 and

- Dusts according to IEC 60079-10 – 2 Guideline- Electrical Apparatus for Explosive Gas Atmosphere or relevant NFPA standards

- NFPA 497 – Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapours and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

- NFPA 70 – National Electric Code

- We Help you to Manage Fire & Explosion Risks in Hazardous Areas

- Our Solution is based on National and International Standards and Best Industry Practices

The uniqueness of Consultivo solutions

- A unique end-to-end solution customised to your existing system and need

- In line with statutory requirements, national and international standards, guidelines and industry best practices

- Practical and competent consulting team comprising of industry experienced Hazardous Area Classification Consultants in India

How Consultivo can help

Remote Support

On-Site Support

Blended Support - Remote & On-site

1.

Hazardous Area Classification

We offer a comprehensive Hazardous Area Classification HAC solution comprising of the following scope:

- Hazardous Area Study and subsequent review of the existing Hazardous Area Classification of the plant against applicable national & international hazardous area classification standard, code, guideline and legal requirements.

- To review the selection of electrical equipment and apparatus installed within the respective hazardous area classification zones and their compliance with the classified area.

Custom made services

Do you have a need for something else in your organisation that does not fit into the scope of a regular HAC?

We are happy to work with you to develop custom- made service that meets your stated needs. You can rely on our expertise to advise and guide you in your journey towards an effective risk management.

Send a mail to [email protected] or Call +91 98311 45556

Featured training courses

How do we do them?

Our Hazardous Area Classification (HAC) studies help you to plan, identify and manage your explosive atmosphere related risks. As a practicing Hazardous Area Classification Consultants in India we acquired a deep understanding of electrical safety, process hazard analysis, standards & legal requirements, process steps and industry insights.

We ensure that the results provide you with information that can help you to manage risks for your people.

The major steps for a HAC study are:

Action item 1: Pre activities

Understanding the scope of work and purpose of HAC based on the appropriate risk levels related to your industry sector, processes and people is the stepping stone. Selecting a small multidisciplinary HAC team from the organisation to support the external experts also play an important role.

Action item 2: Collect Inputs

Collection of existing information about workplace hazards through the physical tour, the study of the plant operations, previous data, discussions with process owners Identification and compilation of flammability data Building and equipment layout

Action item 3: Identify Hazards

Based on action item 2, identify hazards associated with normal or routine, non-routine and emergency situations: Identification of potential release sources Estimation of the release duration Present system of ventilation and its effectiveness Determination of possible ignition mixture(s)

Action item 4: Zone Rating & Documentation

Based on the above-mentioned inputs, the next step is rating and classification of zones as per the applicable Hazardous Area Classification Guide and standards considering country legal requirements. Hazardous Area Classification Zone 0 1 & 2 The most common values used are Zone 0: Explosive atmosphere for > 1000 h/yr. Zone 1: Explosive atmosphere for > 10, but < 1000 h/yr. Zone 2: Explosive atmosphere for < 10 h/yr, but still significant enough to require controls over ignition sources. (Ref HSE)

Action Item 5: Evaluation & Recommendation of Electrical Equipment

Provide recommendations for selection & suitability of electrical equipment and apparatus within the classified zones.

Process Hazard Analysis

Process Hazard Analysis (PHA) is a detailed and specialised approach for identifying, evaluating, and controlling the hazards of processes. They must be appropriate to the complexity of the processes.

Few PHA services offered by Consultivo are

- Hazard and Operability Study (HAZOP)

- Hazard Identification Study (HAZID)

- Quantitative Risk Assessment (QRA)

Find more here

Let's discuss

Impact Stories

The impact we create. The excellence we inspire.

Read a few of our stories as we partner organisations as an ESG and Sustainability Consultant Company and an Advisory Firm.

The internationally reputed company is a major construction, mining and power solutions provider with more than 25 locations in India. Their major challenge was working with multiple standards and legal requirements of different stakeholders.

We started with the development of an inhouse standard and guideline which was implemented across the locations.

We customized our scored assessment protocol ‘Protosafe’ as per their requirements and developed a three year plan. The safety performance scorecard provided the required guidelines to the management for improvement. Our recommendations facilitated the actions.

A definite positive trend of improvements observed in the subsequent years.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

25 Locations across India

4000+ workpersons

Since 2018

Project ongoing till April 2023.

An international automotive manufacturer intended to reduce the OHS risks across the value chain – dealers/workshops. We created a customized OHS audit protocol keeping the focus on the relevant potential hazards and risks. The outcome includes analytics, scoring, benchmarking among the entities.

The project is ongoing for 1200+ units across India.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

1200+ units

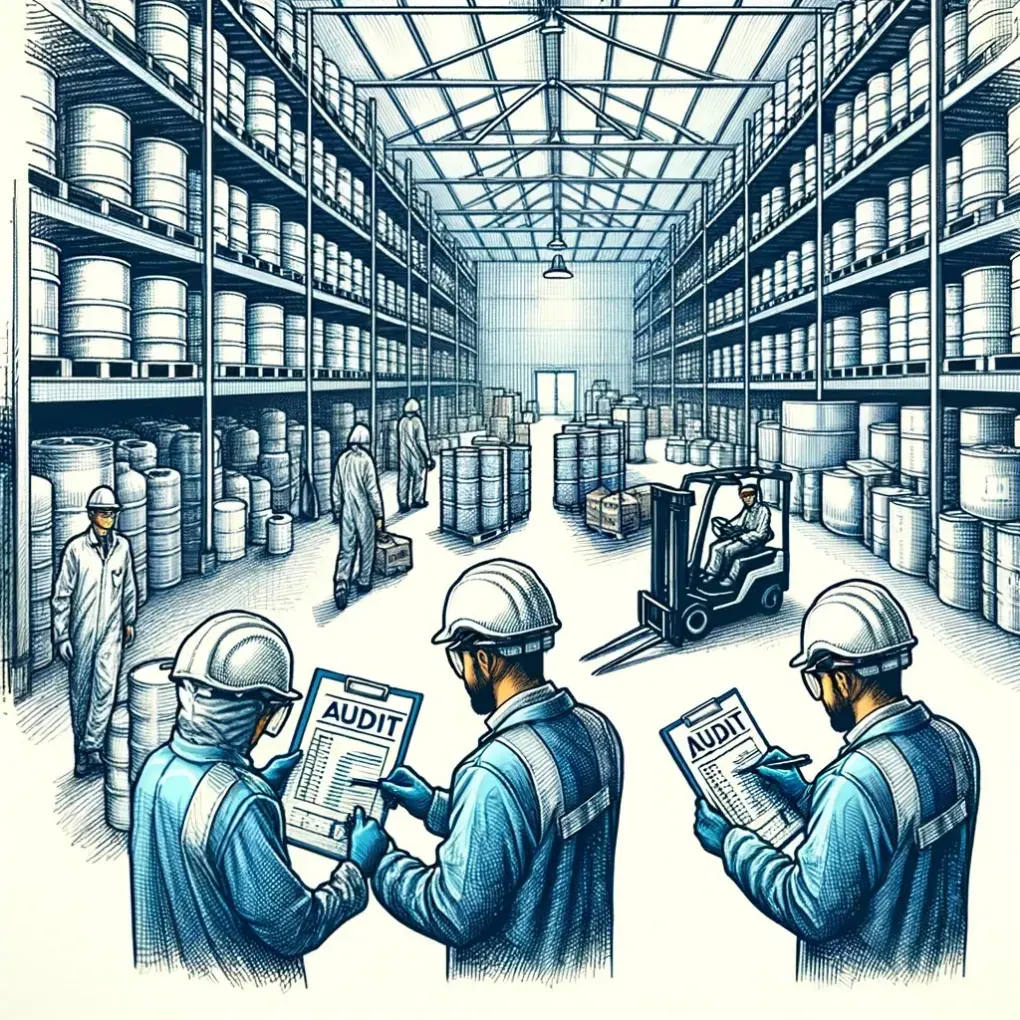

A large Naphtha Based Petrochemical Complex needed statutory safety audit as per IS 14489 standard. This audit was intended for meeting compliance and finding out potential risks from an independent expert perspective.

Consultivo was selected after a rigorous technical evaluation process which was focused on the quality of experience and expertise of both the organization as well as the auditors. The team was carefully chosen with diversified expertise in General Safety, Fire Safety, Process Safety and Electrical Safety with adequate Oil & Gas (Refinery & Petrochemical) experience.

The audit was conducted as per IS 14489:2018 standard and a detailed report was submitted with specific gaps, risks and recommendations.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

One Location with Naptha Cracker Unit and 12 Associated Plants

Captive Power Plant

Pipeline to Jetty

Featured Insights

Knowledge Bank

Impact Stories

Impact Stories

Impact Stories

Impact Stories

Impact Stories

View more in Impact Stories | Blogs | Knowledge Bank | News and Events

Curiosity Zone

Some more answers to your questions – FAQ

Definition of Hazardous Area and Hazardous Area Classification Zoning

When electrical equipment is used in, around, or near an atmosphere that has flammable gases or vapours, flammable liquids, combustible dust, ignitable fibers, or flyings, there is always a possibility or risk that a fire or explosion might occur.

Those areas where the possibility or risk of fire or explosion might occur due to an explosive atmosphere and/or mixture is often called a hazardous (or classified) location/area.

Hazardous areas can be defined as any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers.

In this context, ‘special precautions’ are best taken as relating to the construction, installation, and use of apparatus.

Area classification is a method of analysing and classifying the environment where explosive gas atmospheres may occur. The main purpose is to facilitate the proper selection and installation of the apparatus to be used safely in that environment, taking into account the properties of the flammable materials that will be present.

It is also important to take into account non-electrical sources of ignition, and mobile equipment that creates an ignition risk.

Hazardous Area Classification – Zones

Hazardous Area Classification Guides classify different zones based on an assessment of the frequency of the occurrence and duration of an explosive gas atmosphere, as follows:

- Zone 0: An area in which an explosive gas atmosphere is present continuously or for long periods;

- Zone 1: An area in which an explosive gas atmosphere is likely to occur in normal operation;

- Zone 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time.

The Zone defines the probability of the hazardous material, gas, or dust, being present in such a quantity that it may produce explosive or ignitable mixtures.

When the hazardous areas of a plant have been classified as per Hazardous Area Classification Guide and standards, the remainder will be defined as non-hazardous, sometimes referred to as ‘safe areas’.

Hazardous Area Classification – Class/Division

Note: In general, there are two systems used to classify hazardous areas.

- Class/Division system and

- Zone system

The Class/Division system is used predominantly in the United States and Canada, whereas the rest of the world generally uses the Zone system. However, the Zone System is more prevalent globally. Explore more on zoning systems at the HSE UK website and the Class system at the OSHA website.

Consultivo, being one of the practicing Hazardous Area Classification Consultants in India provides review, assessment & consulting services globally.

Practical considerations while conducting hazardous area classification

It’s important to consider the following points while conducting studies on the classification of hazardous areas:

- To know the scope & purpose of the study including the understanding of the plant & process steps that may influence the classification

- Previous data, if any

- References of applicable national and international hazardous area classification standards, codes and guidelines

- Considering Temperature Class and Gas Groups, Identification and compilation of flammability data

- Considering Statutory requirements

- Drawing a detailed Building and equipment layout of the facilities and physical verification and review of hazardous area classification zones

Consultivo, being one of the practicing Hazardous Area Classification Consultants in India provides review, assessment & consulting services globally.

Consultivo Safety Solutions include HIRA Safety Assessment, Electrical Safety Audit, Statutory Safety Audit, Warehouse Safety, Fire and Electrical Safety, Fire Safety Audit

Find all Safety Consulting Solutions

GLOBAL Experience