Safety Audit & Assurance Methodology

IFC (World Bank Group) Approved Independent Consultant

2K+ safety audits & assessments

in last two years

India, SAARC Countries & Middle East

Ready to serve anywhere you are

14+ years

at the forefront of Safety Advisory Space

20+ types of Industry Sectors

covering Manufacturing, Mining, Power & Utility, Construction, Service, High rise Buildings and Logistics

Safety Audit & Assurance Methodology

Frequency of Safety Audit

The frequency is determined through mutual discussion with the client, taking into account specified or regulatory requirements and any other pertinent factors like:

- Significant changes in management, organization. Processes, systems or technologies that could affect the OS&H system

- Results of recent previous audits

Safety Audit Methodology

Methodology

01 / Audit Plan

At this stage, we transform your requirements into a detailed & structured audit plan.

Our technical experts will share the pre-requisites and understand your need and expectations.

We understand the industry specific challenges

Design the right solution.

Assign Competent Auditors

02 / Audit Activities

Opening meeting with the management

- Physical ‘Walk Through’

- Document review

- Collecting evidences for both compliance & non-compliance

- Closing meeting with management

Hybrid Mode – Combination of Onsite and Online methods

Use of decade long validated audit protocol

Use of Task Observations, Physical Verifications, Interviews

03 / Post Audit

Upon completion of Audit, a detailed report is prepared which includes

Executive Summary

Maturity Level Scoring for each Element & Sub-Element with Dashboard with graphical representation

Recommendations against each identified gap

- Step 1: Pre-audit

Defining the objectives, scope, and criteria for a safety audit:

Each safety audit, assurance, assessment or verification process in Consultivo is based on documented safety audit procedure which includes objectives, scope, and criteria. Physical boundary, processes involved, people exposure, organisation structure, and audit criteria/standard are predetermined before each audit.

The assessment scope includes such factors as physical locations, organisational units, activities and processes to be audited, as well as the time period covered by the audit.

The assessment criteria are used as a reference against which conformity is determined and may include applicable policies, procedures, standards, legal requirements, management system requirements, contractual requirements, sector codes of conduct or other planned arrangements.

Formation of multidisciplinary audit teams:

Safety audits are carried out through multidisciplinary audits teams (consisting of 2 to 4 team members) with necessary experience and background to undertake an in-depth audit in a particular discipline viz. Process, Maintenance, Electrical, Fire & Safety. One of the team members is nominated as the leader of the audit team.

Preparation of Safety Audit Checklists:

Checklists are the most useful tool for undertaking systematic Safety Audits. A mind map or checklist covering important areas and the audit criteria requirements are prepared before each audit.

- Step II: Audit

Opening meeting with the management:

Onsite audit process starts with an opening meeting with the management and the key operational personnel, where the Lead Auditor explains the audit methodology and reporting process.

Audit activities:

- Physical ‘Walk Through’ for basic assessment including task observation

- Document review

- Sample selection & interviewing

- Collecting evidences for both compliance & non-compliance

Closing meeting with management:

Before finalising the report, the audit team initiates a presentation/discussion as feedback to the operating/management personnel of the area/installation.

This provides inputs to the draft report based on the discussions and comments received during the presentation.

- Step III: Post Audit

Reporting:

Upon completion of the audit process, a detailed report is prepared. The report content generally includes:

- Executive summary including graphical performance indicators

- Overall and segmental rating/scoring (applicable for protocol assessment)

- The scope and objectives of the audit, audit methodology, audit team members, audit dates

- Identification of the reference documents against which the audit was conducted (safety system standard, auditee’ s safety manual, etc)

- Evaluation of “As-Is Status” against established safety standards – good practices, non conformities and observations

- Audit team’s judgement of the extent of the auditee’s compliance with the applicable OS&H system standard

- Recommendations for improvement, action plans

- Picture gallery identifying areas of safety improvement

Inovations at Consultivo

Irrespective of where you are in your safety excellence journey, our expert team will be able to give advice and guidance to meet your goals.

Get a scored assessment of your safety system based on the capability maturity model through Consultivo’s protoSafe.

Safety Culture and Behavioural Assessment

Industry & Peer Benchmarking Implementation Support

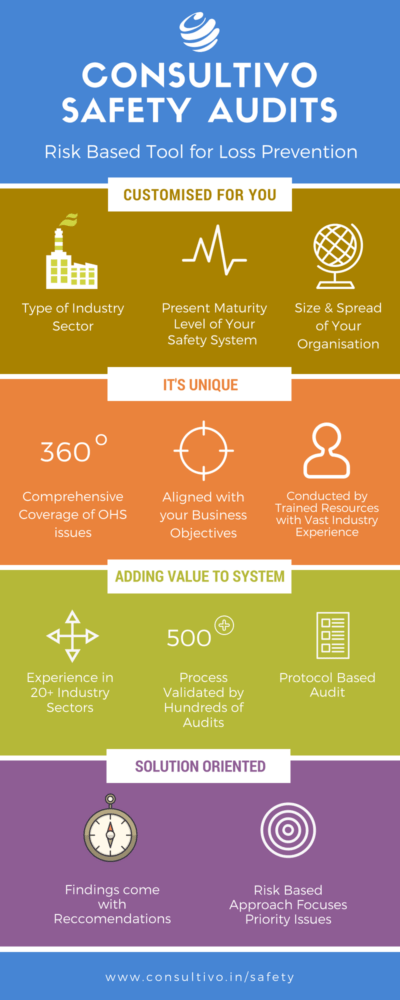

How Consultivo Safety Audit Reports are unique?

Consultivo Safety Assessment Reports reflect what the management needs to know – Risks, Controls, Compliances and Improvement Opportunities.

We depict them through a management dashboard with charts, heatmaps, analytics & benchmarking.

The outcome is backed up by quantitative assessment in line with the safety audit procedure covering activity, process, system, documentation & people.

Become a Certified Auditor with Consultivo Academy

Consultivo Internal Auditor training and certification is a formal recognition that you have demonstrated proficiency within, and acquired a specific level of knowledge and competence on the safety audit procedure.

Remote Audits

Consultivo Remote Audits are full function audit engagements.

Fully remote or coupled with physical audits, remote audits can enable time & cost-efficiency, access to competence, increases reach and mitigate risk.

Let's discuss

Impact Stories

The impact we create. The excellence we inspire.

Read a few of our stories as we partner organisations as an ESG, Sustainability and People Advisory Consulting Firm.

The internationally reputed company is a major construction, mining and power solutions provider with more than 25 locations in India. Their major challenge was working with multiple standards and legal requirements of different stakeholders.

We started with the development of an inhouse standard and guideline which was implemented across the locations.

We customized our scored assessment protocol ‘Protosafe’ as per their requirements and developed a three year plan. The safety performance scorecard provided the required guidelines to the management for improvement. Our recommendations facilitated the actions.

A definite positive trend of improvements observed in the subsequent years.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

25 Locations across India

4000+ workpersons

Since 2018

Project ongoing till April 2023.

An international automotive manufacturer intended to reduce the OHS risks across the value chain – dealers/workshops. We created a customized OHS audit protocol keeping the focus on the relevant potential hazards and risks. The outcome includes analytics, scoring, benchmarking among the entities.

The project is ongoing for 1200+ units across India.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

1200+ units

A large Naphtha Based Petrochemical Complex needed statutory safety audit as per IS 14489 standard. This audit was intended for meeting compliance and finding out potential risks from an independent expert perspective.

Consultivo was selected after a rigorous technical evaluation process which was focused on the quality of experience and expertise of both the organization as well as the auditors. The team was carefully chosen with diversified expertise in General Safety, Fire Safety, Process Safety and Electrical Safety with adequate Oil & Gas (Refinery & Petrochemical) experience.

The audit was conducted as per IS 14489:2018 standard and a detailed report was submitted with specific gaps, risks and recommendations.

Relevant Standards and Protocols used:

Consultivo ProtoSafe, IS 14489, Indian Legal Requirements, ISO 45001

Industry

Construction, power, heavy equipment and services

One Location with Naptha Cracker Unit and 12 Associated Plants

Captive Power Plant

Pipeline to Jetty

Featured Insights

News & Events

Knowledge Bank

Knowledge Bank

Impact Stories

Impact Stories

Impact Stories

View more in Impact Stories | Blogs | Knowledge Bank | News and Events

Curiosity Zone

Some more answers to your questions – FAQ

Consultivo, being a full service safety advisory organisation, conducts a wide range of safety audits for different kinds of industries. Few of them are listed below:

- Comprehensive safety audit as per IS 14489

- Rapid safety audit as per IS 14489

- Construction safety audit

- Fire safety audit

- Electrical safety audit

- Behaviour based safety (BBS) audit

- Chemical safety audit

- Scored safety protocol audit

- Process safety audit

- Logistics safety audit

- Warehouse safety audit

- Any customised safety audit

Audit criteria is defined as the requirements against which we conduct audit. A Safety Audit may have the following criteria:

- IS 14489: Code of practice on occupational safety and health audit

- Relevant Indian Standards – E.g. National Building Code NBC 2016 Part 4 for related requirements in fire safety

- ISO 45001: Occupational Health and Safety Management Systems

- Country specific legal requirements applicable for OHS & other regulatory & obligatory requirements an organisation subscribe to.

- Buyers/customers’ requirements reflected in the contract and purchasing specifications

- Company documents – Policy, Objectives, Risk Assessment, Procedures, Safety Operating Procedures

- Emergency procedures

- Corporate / principal / parent company policies

Consultivo Safety Audit Procedure requires the following considerations before commencing an audit:

- Clearly defined objectives and scope and criteria for the audit

- Team identification and assignments

- Specific audit plan for the audit including timing

- Flowcharts or maps of the processes, areas and activities about to be examined

- Review and preliminary analysis of the formal (documented) requirements

- Communication and agreement with the parties about to be audited

- Work papers prepared to guide the auditors in conducting the audit

- Risk assessment

- Effectiveness of controls

- Compliance to legal requirements

- Adequacy of documentation vis-a-vis requirements

- Competence of personnel

- Housekeeping

- Objectives of the area you are auditing

- Measurements to determine if the process is meeting requirements

- Analysis of data

- Records

- Correction & corrective action

- Improvement

- Evidence of meeting requirements

- Feedback from stakeholders

GLOBAL Experience