Hazardous Area Classification Services

Expert Consultants for Hazardous Area Classification & Compliance

Hazardous Area Classification (HAC) is essential for managing fire and explosion risks in workplaces where flammable substances like gases, vapours, and dust may be present.

Hazardous Area Classification Overview

At Consultivo, we provide specialised Hazardous Area Classification services that help businesses across industries ensure operational safety, regulatory compliance, and risk mitigation.

As one of India’s leading Hazardous Area Classification consultants, our solutions are designed to be unbiased, practical, and aligned with both national and global standards like IS 5572, IEC 60079, ATEX, and NFPA 497.

Our Hazardous Area Classification Services

At Consultivo, we specialise in delivering high-quality Hazardous Area Classification consulting services that ensure the safety, compliance, and operational integrity of industrial facilities.

Our expert team provides precise, standards-aligned documentation and guidance tailored to your unique process and risk profile.

Our services are built on deep domain expertise and compliance with globally recognized standards, including NEC, IEC 60079, ATEX, IS 5572, and OSHA.

Comprehensive Hazard Analysis - Hazardous Area Classification & Risk Study

We identify and evaluate potential sources of ignition and explosive atmospheres based on flammable gases, vapours, dusts, and fibers — forming the foundation for zone classification. This may include

- Classification of Zones (0, 1, 2)

- Review of Existing Hazardous Area Classification Charts

- Hazardous Area Equipment Classification and Verification

- Recommendations for Electrical Safety Upgrades

02.

Compliance Audit as per IEC 60079 and IS 5572 including Regulatory Compliance

We ensure your plant meets all statutory and insurance requirements for hazardous area classification, helping you achieve compliance with national and international codes.

03.

Tailored Hazardous Area Classification Drawings & Zoning Maps

Our team develops detailed and customised Hazardous Area Classification drawings, zoning layouts, and 3D visualisations that align with your facility’s operations and layout.

04.

Technical Recommendations & Expert Advisory

Beyond drawings, we advise on optimal equipment placement, ventilation systems, and safety signage to improve risk mitigation and reduce compliance gaps.

We provide hazardous zone classification support for new plants, existing installations, expansions, and shutdowns across sectors such as:

- Oil & Gas

- Chemical & Petrochemical

- Pharmaceutical

- Power Plants

- Food Processing

- Mining and Metals

What is Hazardous Area Classification?

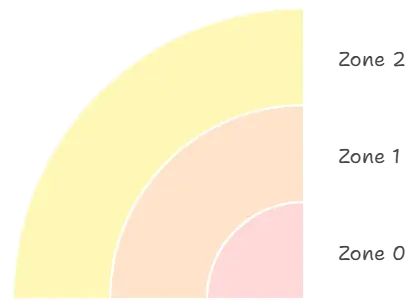

Hazardous Area Classification is the process of identifying locations where there is a risk of explosion due to the presence of flammable gases, vapours, liquids, or combustible dusts. Once identified, these areas are classified into zones — Zone 0, Zone 1, or Zone 2 — depending on the frequency and duration of the presence of explosive atmospheres.

The purpose is to:

- Prevent ignition sources in hazardous areas

- Select appropriate equipment for the zone

- Protect people and assets

- Comply with applicable regulations and standards

The classification serves as the basis for safe design, equipment selection, maintenance, and operations in hazardous locations.

Elevate Your Safety Expertise. Become a HIRA Certified Professional. Register for Our Course!

Why Hazardous Area Classification is Important

Prevent Industrial Fires and Explosions

Many industrial accidents are caused by unaddressed ignition sources in flammable environments. HAC helps prevent these by applying control measures.

Serving clients across India, Middle East, and Southeast Asia

"Ensure Safety. Start Your Hazardous Area Classification Today!"

Start Your Hazardous Area Classification Today

A minor mistake in zone classification can lead to a major disaster. Let’s prevent that together.

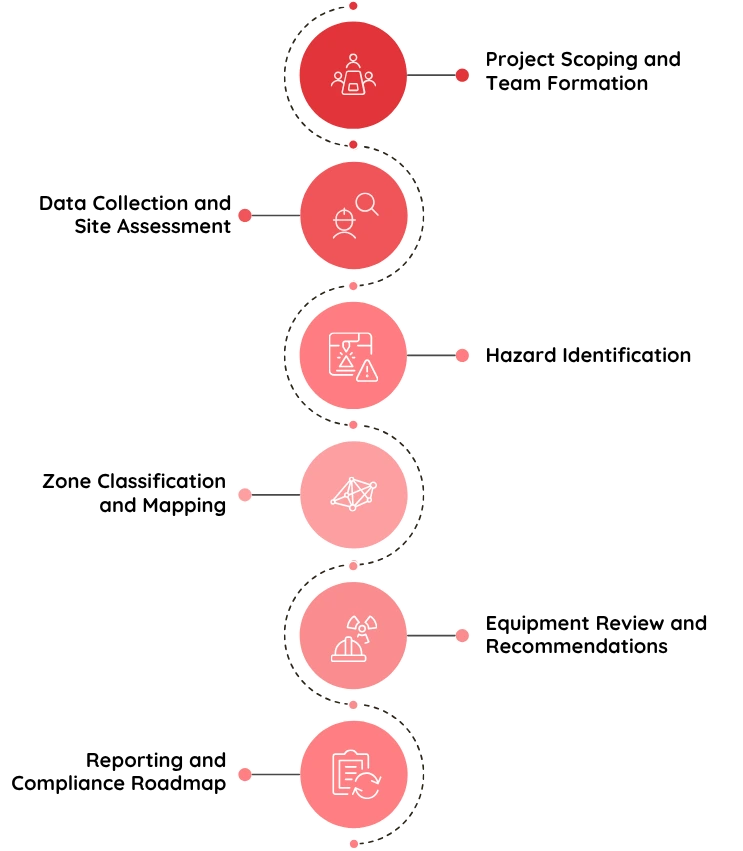

Our Hazardous Area Classification Study Process

01

Project Scoping and Team Formation

We define the scope of the Hazardous Area Classification study, identify critical process areas, and form a joint team with your experts for seamless collaboration.

02

Data Collection and Site Assessment

Our team visits the site, studies the plant layout, ventilation systems, and operations. We gather flammability data, historical incident records, and process flow diagrams.

03

Hazard Identification

We identify sources of potential release – valves, pumps, storage areas – and evaluate normal, abnormal, and emergency conditions.

04

Zone Classification and Mapping

We assign Zone 0, Zone 1, or Zone 2 ratings to each identified hazardous area, based on international best practices and local standards.

05

Equipment Review and Recommendations

We assess all electrical and non-electrical equipment installed in hazardous zones. Mismatches are flagged, and safer alternatives are recommended.

06

Reporting and Compliance Roadmap

We deliver detailed Hazardous Area Classification charts, zoning maps, compliance gaps, and action plans – all tailored to your industry and statutory obligations

Explore Our Related Services:

GLOBAL Experience

Helping to protect lives at workplace

Consultivo offers comprehensive support to organisations in meeting the growing loss prevention & risk management requirements.

2K+ safety advisory projects

in last two years

India, SAARC Countries & Middle East

Ready to serve anywhere you are

14+ years

at the forefront of Safety Advisory Space

20+ types of Industry Sectors

covering Manufacturing, Mining, Power & Utility, Construction, Service, High rise Buildings, Logistics and many more

Frequently Asked Questions (FAQs)

Questions? We have answers.

What exactly is a hazardous area?

A hazardous area is a location where the atmosphere may contain flammable gases, vapours, or dusts in quantities that can cause explosions or fire. These areas need special safety design and equipment installation. HAC helps in identifying and managing such areas.

What are Zones 0, 1, and 2?

These zones define the level of risk in a hazardous area:

- Zone 0: Flammable atmosphere is continuously present (more than 1000 hours/year)

- Zone 1: Flammable atmosphere is likely during normal operations (10–1000 hours/year)

- Zone 2: Flammable atmosphere is unlikely during normal operations, but if it occurs, it exists only for a short time (<10 hours/year)

These definitions help determine what equipment is suitable for use in each zone.

What is the difference between a Zone system and Class/Division system?

- The Zone system is widely used in Europe, India, and globally.

- The Class/Division system is used in North America (USA, Canada).

At Consultivo, we work with both systems depending on your regulatory environment and project location.

Which standards do you follow for Hazardous Area Classification?

We follow global and Indian standards including:

- IS 5572 – Indian standard for classification of hazardous areas

- IEC 60079 series – International Electrotechnical Commission standards

- NFPA 497 and 70 (NEC) – US codes for flammable areas

- ATEX Directive – For European projects

We also reference OSHA, HSE, API, and industry-specific best practices.

What are the key documents I will receive from the study?

You will receive:

- Hazardous Area Classification Report

- Zoning Layout Drawings

- Equipment Compliance Review

- Risk Control Recommendations

- Applicable Codes and Standards Mapping

These documents can be used for audits, statutory compliance, and insurance purposes.

Can existing hazardous areas be reclassified?

Yes, if there are changes in plant layout, materials handled, ventilation, or safety systems, we can help review and reclassify hazardous areas. Regular reviews are also recommended as part of good safety management.

Does HAC include non-electrical equipment?

Yes. In modern standards, non-electrical ignition sources like hot surfaces, static discharge, or friction can be just as dangerous. Our studies take all ignition sources into account.

Why Choose Consultivo?

Industry-Leading Expertise

Our hazardous zone classification consultants bring years of experience across sectors like oil & gas, chemicals, pharmaceuticals, and manufacturing.

Global Standard Alignment

Every document and design we deliver is aligned with IEC, NEC, ATEX, IS 5572, and OSHA guidelines.

Accuracy and Clarity

Our drawings are technically accurate, audit-ready, and easy to interpret — designed for both operational teams and external auditors.

Efficient Turnaround

With a streamlined process and digital collaboration tools, we ensure timely delivery without compromising on quality.

About Consultivo

Consultivo is a leading ESG & Sustainability advisory firm, supporting global businesses in achieving sustainable growth through strategic and operational excellence.

We operate through four integrated practice areas—Audit, Consulting, Research, and Training—across six key domains:

ESG & Sustainability, Community & CSR, Safety, Environment, Energy & Climate Risks, and People Advisory & Business Excellence.

As part of our Safety solutions, we offer a full suite of services that help organisations identify, assess, and mitigate risks to ensure safer workplaces. From process safety and risk assessment to hazardous area classification, our expert-driven, standards-based approach supports compliance, operational continuity, and employee well-being.

Browse our Featured Blog

Read a few of our stories as we partner organisations as an ESG, Sustainability and People Advisory Consulting Firm.

Browse our Impact Stories

Read a few of our stories as we partner organisations as an ESG and Sustainability Due Diligence Audit Firm.

Speak to us or drop us a WhatsApp message

Let's discuss