Making sense of hazardous zone classification to keep workplaces safe.

Hazardous zone classification is crucial for safety where flammable materials exist. This blog post explains how to identify risky zones, choose the right equipment, and follow safety rules to prevent explosions and protect everyone.

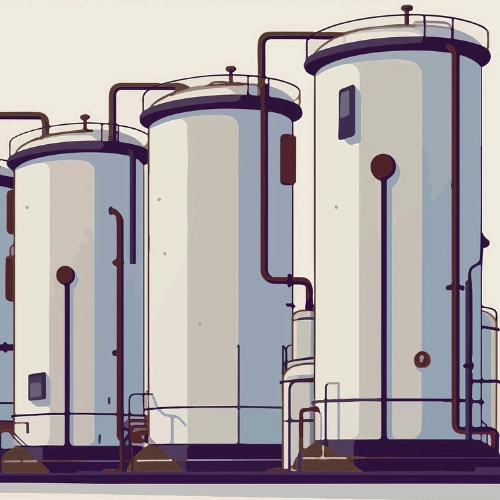

Working with flammable gases, vapours, mists, or combustible dusts presents significant risks. Industries from oil and gas to pharmaceuticals, chemicals, and food processing regularly encounter environments where an explosive atmosphere could form. Managing these risks effectively is paramount for worker safety, operational continuity, and regulatory compliance. This is where hazardous area classification becomes indispensable.

Understanding and implementing proper hazardous area or hazardous zone classification is not just a regulatory formality; it is a critical safety measure that underpins the design, installation, and maintenance of equipment in potentially explosive atmospheres.

This comprehensive guide will demystify the complexities of hazardous zone classification, explaining its importance, methodologies, and practical applications to help you protect your workplace.

What is hazardous zone classification?

Hazardous zone classification is a method of analysing and classifying places where explosive atmospheres may occur. It involves identifying areas where flammable substances are, or may be, present in quantities sufficient to create a flammable or explosive mixture with air.

Once identified, these areas are then categorised into specific zones based on the likelihood and duration of an explosive atmosphere’s presence.

The primary goal of hazardous area classification is to facilitate the safe selection and installation of equipment. By classifying an area, organisations can ensure that only appropriately certified equipment – designed and tested to prevent ignition sources – is used.

This rigorous approach significantly reduces the risk of explosions and fires, safeguarding personnel and assets.

Why is hazardous zone classification crucial for workplace safety?

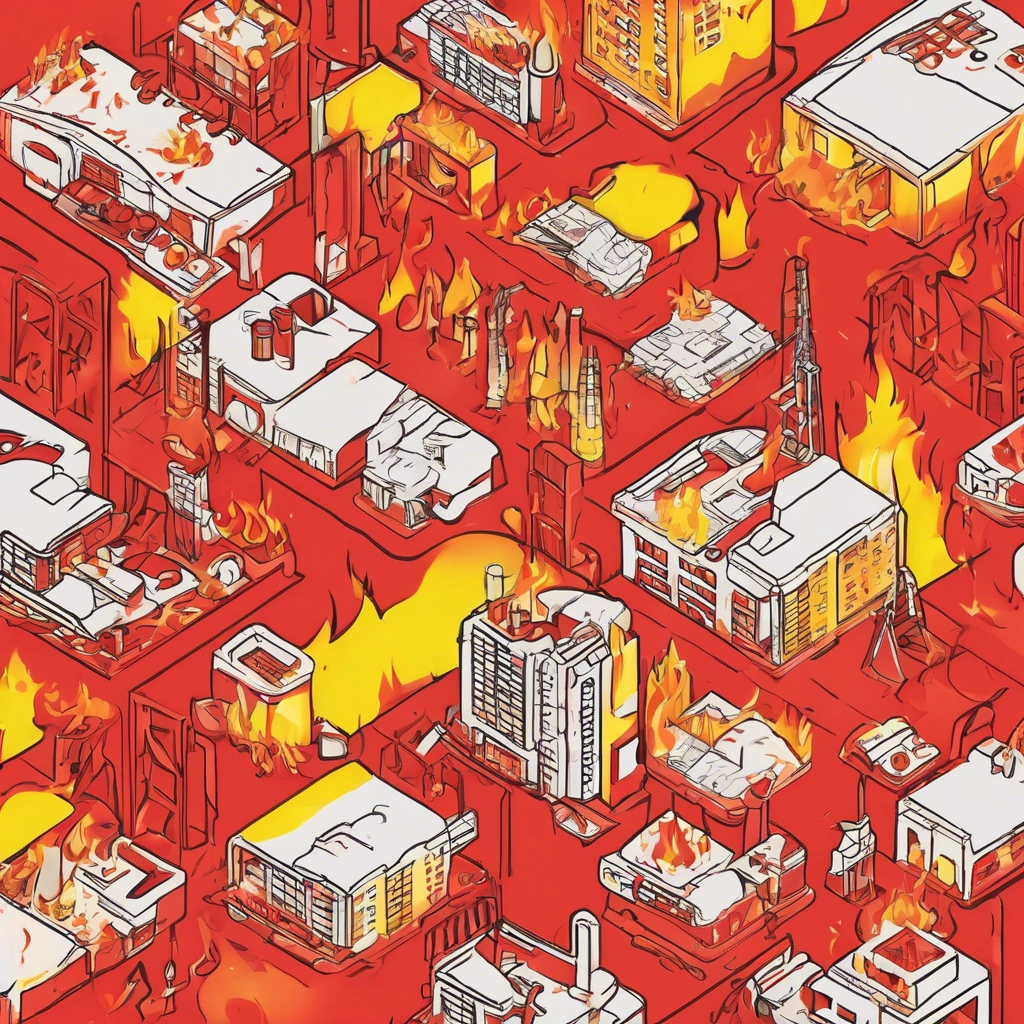

Ignoring or improperly executing hazardous zone classification can lead to catastrophic consequences. Explosions in industrial settings can result in severe injuries, fatalities, extensive property damage, and significant financial losses.

Beyond the immediate impact, such incidents can lead to legal penalties, reputational damage, and business disruption.

Proper hazardous zone classification enables organisations to:

- Prevent explosions and fires: By identifying potential ignition sources and ensuring only suitable equipment is used.

- Protect personnel: Minimising the risk of injuries and fatalities from explosive atmospheres.

- Ensure regulatory compliance: Adhering to national and international safety standards and regulations.

- Reduce operational risks: Preventing costly downtime, equipment damage, and business interruptions.

- Optimise equipment selection: Avoiding over-specification or under-specification of equipment, leading to cost efficiencies and enhanced safety.

The fundamentals of hazardous zone classification

The core of hazardous zones classification revolves around defining “zones.” These zones delineate areas based on the probability of an explosive atmosphere being present. The classification considers the properties of the flammable substance (gas, vapour, mist, or dust) and the ventilation conditions within the area.

The international standard IEC 60079-10-1 (for gases and vapours) and IEC 60079-10-2 (for combustible dusts) provide the framework for hazardous areas classification.

In India, IS 5572 is a key standard that aligns with these international principles.

Gases, vapours, and mists: The zone 0, 1, 2 system

For gases, vapours, and mists, the hazardous area classification is typically divided into three primary zones:

- Zone 0: An area in which an explosive atmosphere is present continuously or for long periods or frequently. This is the highest risk category. Examples include the inside of a storage tank for a flammable liquid or the immediate vicinity of a vent from a continuously flowing flammable gas.

- Zone 1: An area in which an explosive atmosphere is likely to occur in normal operation occasionally. This includes areas around relief valves, pump seals, or flanges where leaks might occur during normal operation.

- Zone 2: An area in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist only for a short period. This could be areas around sealed systems where a leak is only expected under abnormal conditions, or areas adjacent to Zone 1 where dilution would rapidly reduce concentration.

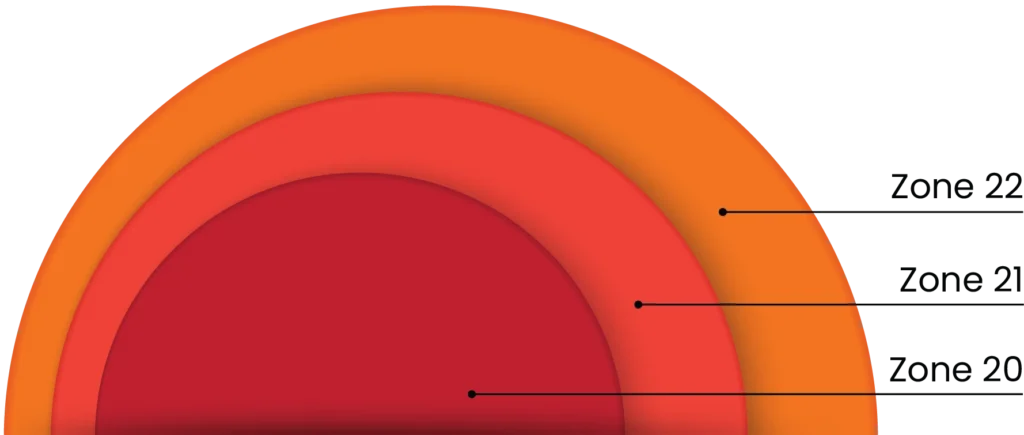

Combustible dusts: Zone 20, 21, 22

While the principles are similar, combustible dusts have their own sets of zones, reflecting the different nature of dust explosions:

- Zone 20: An area in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently. This is common inside dust collectors, cyclones, and conveying systems.

- Zone 21: An area in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur occasionally in normal operation. This might include areas near filling or emptying operations where dust clouds can form.

- Zone 22: An area in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist only for a short period. These can be areas where dust might accumulate and could become airborne under unusual circumstances, like a spill.

The process of hazardous zone classification

Performing a thorough hazardous area classification requires a systematic approach, often involving a team of experts. Here are the key steps:

1. Identifying flammable materials

The first step is to identify all flammable gases, vapours, mists, and combustible dusts present in the workplace. This involves reviewing Safety Data Sheets (SDS) to understand their properties, such as flash point, auto-ignition temperature, lower explosive limit (LEL), and upper explosive limit (UEL).

2. Identifying sources of release

Once flammable materials are identified, the next step is to pinpoint potential sources of release. This includes:

- Continuous grade releases: Those that are continuous or expected to occur for long periods. Examples include the surface of flammable liquid in an open vessel.

- Primary grade releases: Those that are likely to occur periodically or frequently during normal operation. Examples include pump glands, valve stems, or flanges.

- Secondary grade releases: Those that are not expected to occur in normal operation but could occur due to equipment malfunction or abnormal conditions. Examples include a pipe rupture or a cracked vessel.

3. Determining ventilation

Ventilation plays a crucial role in diluting explosive atmospheres. The effectiveness of ventilation systems (natural or mechanical) needs to be assessed. Factors like air changes per hour, airflow patterns, and the reliability of the ventilation system are critical.

4. Defining zone boundaries

Based on the type of release and ventilation effectiveness, the boundaries of each zone (Zone 0, 1, 2 or Zone 20, 21, 22) are determined. This often involves calculations, modelling, and expert judgment. The resulting hazardous area classification chart provides a visual representation of these zones.

5. Documenting the classification

A detailed report documenting the entire hazardous classification process is essential. This report should include:

- A list of all flammable materials.

- Descriptions of release sources and their grades.

- Ventilation assessments.

- Detailed drawings showing the extent of each area classification zone.

- Justifications for the chosen classifications.

This documentation serves as a critical reference for selecting appropriate hazardous area equipment classification and for future reviews.

Request for: hazardous area classification pdf or a hazardous area classification ppt for easy reference and training purposes.

Hazardous area equipment classification and selection

Once the hazardous area is classified, the next crucial step is to select and install appropriate hazardous area equipment classification. Equipment used in these zones must be specifically designed and certified to prevent ignition.

The ATEX directives (Directive 2014/34/EU and Directive 1999/92/EC) are widely recognised standards in Europe for equipment intended for use in potentially explosive atmospheres. Similar standards exist globally, such as the IECEx System.

Equipment is classified into categories based on the zone in which it can be safely used:

- Category 1 equipment: Suitable for Zone 0 (for gases/vapours) or Zone 20 (for dusts) – designed to operate continuously or for long periods.

- Category 2 equipment: Suitable for Zone 1 (for gases/vapours) or Zone 21 (for dusts) – designed for normal operation where explosive atmospheres are likely to occur occasionally.

- Category 3 equipment: Suitable for Zone 2 (for gases/vapours) or Zone 22 (for dusts) – designed for normal operation where explosive atmospheres are not likely to occur but, if they do, will persist for only a short period.

Beyond the category, equipment also needs to be marked with the appropriate gas or dust group and temperature class, ensuring it does not become an ignition source. This rigorous hazardous area classification standard ensures that safety is embedded in the equipment design and selection.

The role of consultants and agencies in hazardous area classification

Given the complexities and the critical safety implications, many organisations opt to engage hazardous area classification consultants or hazardous area classification agencies. These specialists bring deep expertise and experience, ensuring accurate and compliant classifications.

Hazardous zone classification consultants can provide:

- Expert assessment: Conducting thorough site surveys and hazard identification.

- Detailed documentation: Preparing comprehensive hazardous area classification reports and drawings.

- Compliance assurance: Ensuring adherence to relevant national and international standards (e.g., IS 5572, ATEX, IECEx).

- Training: Educating in-house teams on the principles and practices of area classification.

- Risk mitigation strategies: Advising on measures to reduce the extent of hazardous zones.

- Ongoing review: Assisting with periodic reviews and updates to the classification as processes or equipment change.

Engaging hazardous area classification services from reputable hazardous zone classification consultants helps mitigate risks, ensures regulatory compliance, and provides peace of mind.

They can also assist with specific queries, such as providing a hazardous area classification pdf of relevant guidelines or conducting workshops using a hazardous area classification ppt.

Integrating hazardous area classification with broader sustainability and ESG themes

While primarily a safety concern, effective hazardous area classification aligns seamlessly with broader sustainability and Environmental, Social, and Governance (ESG) principles.

A robust safety culture, underpinned by practices like rigorous hazardous area classification, contributes directly to the “Social” pillar of ESG. By preventing accidents, safeguarding workers, and ensuring operational continuity, companies demonstrate their commitment to human capital and responsible business practices.

Furthermore, reducing the risk of explosions often involves optimising processes, improving containment, and potentially reducing the overall quantity of hazardous materials.

These measures can indirectly contribute to environmental protection by minimising potential releases and promoting more efficient resource use. A well-classified and managed hazardous area also reduces the likelihood of environmental contamination resulting from an industrial incident.

Companies that prioritise a high level of safety management, including diligent hazardous zone classification, often exhibit stronger overall governance. This demonstrates proactive risk management, adherence to regulations, and a commitment to continuous improvement, all of which are vital components of a mature ESG strategy.

The focus on preventing harm to people and the environment is intrinsically linked to the Sustainable Development Goals (SDGs), particularly SDG 3 (Good Health and Well-being) and SDG 8 (Decent Work and Economic Growth).

Conclusion

Hazardous area classification is a fundamental pillar of safety in industries dealing with flammable substances. It is a meticulous process that requires expert knowledge, diligent application of standards, and ongoing attention. From identifying the properties of hazardous materials to defining specific hazardous zones and selecting appropriate hazardous area equipment classification, each step is critical for preventing catastrophic incidents.

By embracing a proactive approach to hazardous area classification, supported by comprehensive documentation, regular reviews, and potentially the expertise of hazardous area classification consultants, businesses can significantly enhance workplace safety, ensure regulatory compliance, and foster a resilient operational environment.

This commitment not only protects lives and assets but also reinforces a company’s dedication to responsible and sustainable business practices.

Share this post

Category: Blog

Tags: Safety | Hazardous Area Classification

Related insights