Safety and reliability are no longer support functions. They are core business capabilities.

Organisations that want stable operations, strong ESG performance, and long-term resilience must focus on reliability and safety together.

A strong safety culture improves safety performance, reduces operational variation, and builds trust across the workforce. It also strengthens business reliability.

At Consultivo, we define safety culture as the integration of two critical pillars:

A strong Occupational Health and Safety Management System (OHSMS)

A well-designed behavioural safety programme that shapes how people act at work

This article explains how reliability by design in safety, through systems and behaviour, creates a predictable and positive workplace safety culture.

What you will find here

Safety and Reliability in Safety Culture: Where Systems Meet Human Performance

Safety and reliability go beyond legal compliance.

A PDCA-based Safety Management System such as ISO 45001 provides structure and governance.

Human performance principles ensure these controls work during real operations.

For reliability in safety, organisations need:

- Clear processes that define safe work expectations

- Competent people who can work safely under pressure

- Leadership that reinforces safety through action, not slogans

- Systems that promote reporting, learning, and improvement

- A culture that focuses on prevention, not blame

This is where safety and reliability come together in practice.

The Two-Pillar Model of Safety and Reliability in Safety Culture

A predictable safety culture rests on two equally important pillars:

Systems and Behaviour.

Pillar 1: The Conventional System Pillar for Reliability and Safety

This pillar is built on a formal OHSMS, commonly aligned with ISO 45001.

It uses the PDCA cycle — Plan, Do, Check, Act — to manage hazards and risks.

Key system elements include:

- Hazard Identification and Risk Assessment (HIRA)

- Evaluation of probability and severity

- Control selection using the hierarchy of controls

- Residual risk management

- Management of high-risk tasks using:

- CTA (Critical Task Analysis)

- JSA (Job Safety Analysis)

- LOTO (Lock Out Tag Out)

- Permit to Work systems

- Fatality Prevention Elements (FPE)

- Safety audits, inspections, surveys, and reviews

Strong systems improve baseline safety performance.

However, systems alone cannot guarantee reliability and safety.

A conventional OHSMS cannot, by itself, create a positive safety culture.

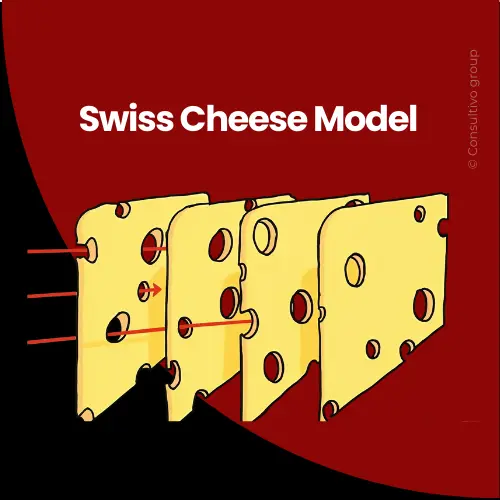

The Challenge: Bridging System Design and Human Behaviour in Safety and Reliability

The main challenge in safety culture is managing the interaction between:

- Robust systems and procedures

- Variable human behaviour

Even the best-designed safety system will fail if:

- Unsafe acts are repeated

- Unsafe conditions are ignored

- Deviations become normal

Most incidents involve unsafe acts and unsafe conditions.

Behaviour plays a critical role in safety outcomes.

This is why managing at-risk behaviour is essential for reliability in safety.

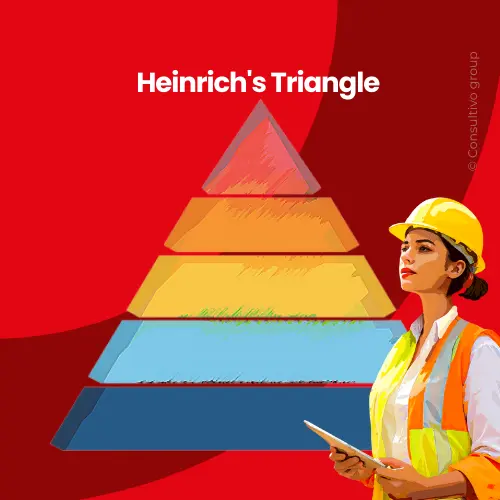

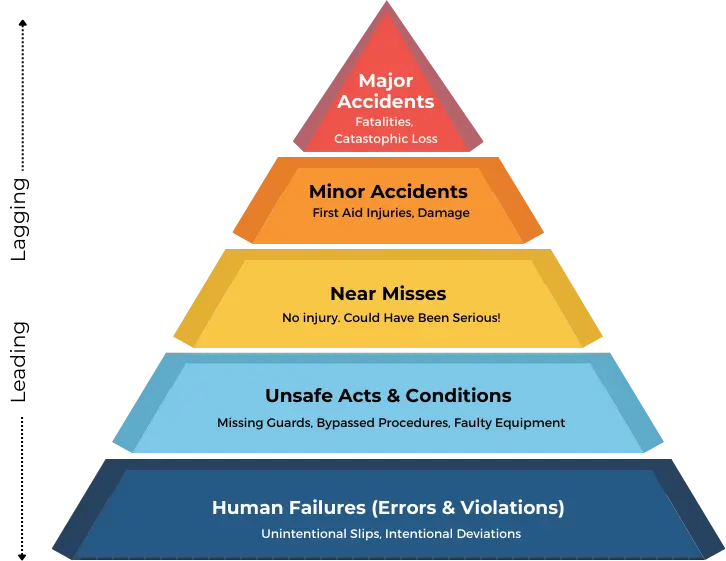

Heinrich’s Triangle: A Statistical Case for Reliability and Safety

Heinrich’s Accident Triangle explains why focusing only on serious accidents does not improve safety performance.

The model shows that:

- For every major injury, there are many minor injuries

- Below these are hundreds of near misses

- At the base are unsafe acts and unsafe conditions

Classic ratios suggest:

- 1 serious injury

- 29 minor injuries

- 300 near misses or no-injury events

To improve safety and reliability, organisations must control the base of the pyramid.

The Solution: Reliability by Design in Safety Through Behaviour-Based Safety

This is where Behaviour-Based Safety (BBS) becomes critical.

BBS focuses on:

- Unsafe acts

- Unsafe conditions

- Everyday behaviours that create risk

By reducing unsafe behaviour, the entire accident triangle shrinks.

This improves safety performance and prevents severe incidents.

Pillar 2: The Behavioural Pillar for Reliability and Safety

The behavioural pillar strengthens how people interact with systems.

It includes:

- Behaviour-Based Safety approaches

- The ABC model (Antecedent, Behaviour, Consequence)

- Structured behaviour-based safety observations

- Feedback and coaching

- Fair consequence management

- Trend analysis of unsafe acts and unsafe conditions

Advanced organisations also use:

- HEART (Human Error Assessment and Reduction Technique)

- THERP (Technique for Human Error Rate Prediction)

- Human and Organisational Performance (HOP)

Together, these tools reduce human error and improve reliability in safety.

Start your safety culture development journey

Elements of a Robust Safety and Reliability Culture

A strong safety culture works like an iceberg.

Some elements are visible. Others are hidden but more powerful.

Visible Elements of Safety and Reliability (Above the Waterline)

These are easy to observe and measure:

- Safe work behaviours

- Compliance with procedures

- Use of PPE

- Participation in safety observations

- Reporting of hazards and near misses

Invisible Elements of Safety and Reliability (Below the Waterline)

These elements drive visible behaviour:

- Values that prioritise safety over speed or cost

- Trust in reporting without fear of blame

- A proactive mindset towards risk

- Care and empathy between colleagues

- Belief that zero harm is achievable

A mature safety culture ensures both layers work together.

From HIRA to HOP: Building Predictable Safety Performance and Reliability

Predictable safety performance improves when systems and behaviour align.

This requires:

- HIRA to identify hazards and controls

- Behavioural insights to ensure controls are followed

- HOP to support learning from failure

- Leadership that reinforces safe choices

Tools like HEART and THERP further improve reliability by reducing human error during critical tasks.

This integration reduces variability and improves safety and reliability.

Safety as a Capability: Controls, Conversations, and Consequences

A mature organisation treats safety as a capability, not a programme.

This capability rests on three elements:

Controls for Reliability and Safety

Controls form the foundation.

They must be well designed, verified, and maintained.

Conversations That Strengthen Safety Culture

Regular safety conversations build trust:

- Coaching and feedback

- Toolbox talks

- Safety interventions

- Post-task reviews

Consequences That Reinforce Reliability and Safety

Positive reinforcement and fair accountability shape behaviour.

Consistency is critical.

Together, these elements create a positive safety culture.

The Anatomy of Safety and Reliability Culture

A reliable safety culture is shaped by:

- Visible leadership commitment

- Skilled and competent teams

- Clear controls for high-risk work

- Reporting systems that promote learning

- Safety culture surveys

- Capacity-building programmes such as BBS safety training

- Safe workplace design

- Strong operational discipline

When aligned, these drivers create a resilient safety culture.

Role of Training in Safety and Reliability Culture

Training is essential for building capability.

Effective programmes cover:

Behavioural Training

- Behaviour-Based Safety (BBS)

- Observation skills

- Identifying unsafe acts and conditions

- Feedback and coaching

- Tools such as BBS implementation, BBS PPT, behaviour based safety PPT

System and Technical Training

- HIRA

- Incident investigation

- Permit to work

- Emergency response

- Operational discipline

Leadership Training

- Safety leadership skills

- Conducting structured safety interactions

- Reinforcing positive safety culture

Training moves safety from awareness to skill.

Capacity building moves it from compliance to practice.

How Behaviour-Based Safety Improves Safety and Reliability

A strong BBS programme:

- Improves observation quality

- Reduces unsafe behaviour

- Strengthens learning from near misses

- Enables early risk identification

It shifts organisations from reactive to proactive safety management.

This is essential for a mature and reliable safety culture.

Connecting Safety Culture to Operational Reliability

A strong safety culture delivers benefits beyond compliance:

- Lower operational variability

- Higher productivity

- Reduced downtime

- Improved ESG outcomes

- Better workforce morale

- Stronger audit performance

- Lower accident-related costs

- Organisations with strong safety culture also show higher trust and transparency.

Organisations with strong safety culture also show higher trust and transparency.

Safety and Reliability as a Long-Term Strategy

Safety culture is a reliability strategy.

It is not a single initiative.

Organisations that integrate:

- Robust systems

- Human performance

- Leadership behaviour

create a predictable and sustainable safety culture.

This shift towards reliability by design in safety, integrating systems and behaviour, is a defining trend in safety excellence today.

Start your bbs safety journey today

Safety Culture Transformation

Solution Areas

Related Blogs

Let's discuss

Share this post

Category: Blog

Tags: Safety, Behaviour Based Safety, Safety Culture, Human Error in Safety

About the author

CEO and Chief Mentor of Consultivo

Saikat Basu is an experienced strategic and operational risk management professional with a strong global track record in ESG consulting, auditing, and training. Passionate about capacity building, he has delivered numerous programmes across sectors, helping organisations strengthen safety, sustainability, and responsible business performance.

He is the principal architect and co-creator of Consultivo’s SMILe Safety Culture Transformation Framework, integrating behavioural science with practical organisational change. Saikat has worked with 200+ international and national standards in ESG, safety, and sustainability assurance.

He serves as a jury member for leading SHE, Environment, and Social Impact awards, and is a visiting faculty at various academic and industry platforms. A committed writer and thought leader, Saikat regularly contributes insights on safety culture, behavioural safety, ESG, risk management and responsible business.

Related insights

View more in Impact Stories | Blogs | Knowledge Bank | News and Events